SAP BI

- Jeevan

- About this blog: We are posting about SAP BI/BW information. It will help for SAP BI and BO learners.

Wednesday, December 28, 2011

Monday, December 19, 2011

Useful SAP Tables

TABLES IN SAP

1 Customising

1.1 General settings

1.1.1 Countries

T005 Countries

1.1.2 Currency

TCURC Currency codes

TCURR Wisselkoersen

TCURT Currency name

TCURX Decimal places for currencies.

1.1.3 Unit of measure

T006 Units of measure

1.1.4 Calendar functions

T247 Month names

TFACD Factory calendar definition

T015M Month names

TTZZ Time zones

TTZD Summer time rules

TTZDF Summer time rules (fixed annual dates)

TTZDV Summer time rules (variable dates)

TTZDT Summer time rules texts

TTZ5 Assign Time Tones to Countries

TTZ5S Assign time zones to regions

1.2 Enterprise structure

1.2.1 Definition

FI T880 Company

T001 Company code

CO TKA01 Controlling area

LO T001W Plant / sales organisation

T499S Locations

TSPA Division

SD TVKO Sales organisation / company code

TVTW Distribution channel

TVBUR Sales office

TVKBT Sales office text

TVKGR Sales group

TVGRT Sales group text

T171T Sales district text

MM T001L Storage locations

T024E Purchasing organization

T3001 Warehouse number

TVST Shipping point

TVLA Loading point

TTDS Transportation

1.2.2 Assignment

CO TKA02 Assign company code to controlling area

LO T001K Assign plant (valuation area) to company code

SD TVKO Sales organisation / company code

TVKOV Distribution channel / sales organisation

TVKOS Division to sales organization

TVTA Sales aria

TVKBZ Sales office to sales area

TVBVK Sales group to sales office

TVKWZ Plants to sales organization

MM T024E Purchasing organization / company code

T024W Plant to Purchase organization

T001K Link plant ( = valuation area) / company code

TVSWZ Shipping point to plant

T320 Assignment MM Storage Location to WM Warehouse

1.3 Financial accounting

1.3.1 Company code

T004 Chart of accounts

T077S Account group (g/l accounts)

T009 Fiscal year variants

T880 Global company data

T014 Credit control area

1.3.2 Fi document

T010O Posting period variant

T010P Posting Period Variant Names

T001B Permitted Posting Periods

T003 Document types

T012 House banks

1.4 Not categorized

T007a Tax keys

T134 Material types

T179 Materials: Product Hierarchies

T179T Materials: Product hierarchies: Texts

TJ02T Status text

TINC Customer incoterms

TVFK Billing doc types

T390 PM: Shop papers for print control

2 Basic data / administration

2.1 Workbench related tables

2.1.1 Data dictionary tables

DD02L Tables in SAP

DD02T Tables description

DD03L Field names in SAP

DD03T Field description in SAP

2.1.2 Workbench

TADIR Directory of R/3 Repository Objects

TRDIR System table TRDIR

TFDIR Function Module

TLIBG Person responsible for function class

TLIBT Function Group Short Texts

TFTIT Function Module Short Text

TSTC Transaction codes in SAP

TSTCT Transaction codes texts

T100 Message text (vb e000)

VARID Variant data

D020T Screen texts

TDEVC Development class

TDEVCT Texts for development classes

2.2 Administration

2.2.1 User administration

USR01 User master

USR02 Logon data

USR03 User address data

USR04 User master authorizations

USR11 User Master Texts for Profiles (USR10)

UST12 User master: Authorizations

USR12 User master authorization values

USR13 Short Texts for Authorizations

USR40 Prohibited passwords

TOBJ Objects

TOBC Authorization Object Classes

TPRPROF Profile Name for Activity Group

DEVACCESS Table for development user

2.2.2 Batch input queue

APQD DATA DEFINITION Queue

APQI Queue info definition

2.2.3 Job processing

TBTCO Job status overview table

TBTCP Batch job step overview

2.2.4 Spool

TSP02 Spool: Print requests

2.2.5 Runtime errors

SNAP Runtime errors

2.2.6 Message control

TNAPR Processing programs for output

NAST Message status

NACH Printer determination

2.2.7 EDI

EDIDC Control record

EDIDD Data record

EDID2 Data record 3.0 Version

EDIDS EDI status record

EDPAR Convert External < > Internal Partner Number

EDPVW EDI partner types

EDPI1 EDI partner profile inbound

EDPO1/2/3 EDI partner profile outbound

2.2.8 Change documents

CDHDR Change document header

CDPOS Change document positioned

JCDS Change Documents for System/User Statuses (Table JEST)

2.2.9 Reporting tree table

SERPTREE Reporting: tree structure

2.2.10 LIS structure/control tables

TMC4 Global Control Elements: LIS Info Structure

3 MASTER DATA:

3.1 Material master:

MARA Material master

MAKT Material text

MARC Material per plant / stock

MVKE Material master, sales data

MARD Storage location / stock

MSKA Sales order stock

MSPR Project stock

MARM Units of measure

MEAN International article number

PGMI Planning material

PROP Forecast parameters

MAPR Link MARC <=> PROP

MBEW Material valuation

MVER Material consumption

MLGN Material / Warehouse number

MLGT Material / Storage type

MPRP Forecast profiles

MDTB MRP table

MDKP Header data for MRP document

MLAN Tax data material master

MTQSS Material master view: QM

3.1.1 Basic data text (sap script)

STXB SAP script: Texts in non-SAP script format

STXH STXD SAP script text file header

STXL STXD SAP script text file lines

3.1.2 Batches

MCHA Batches

MCH1 Batches

MCHB Stock: batches

3.2 Customer master data

KNA1 Customer master

KNB1 Customer / company

KNVV Customer sales data

KNBK Bank details

KNVH Customer hierarchy

KNVP Customer partners

KNVS Shipment data for customer

KNVK Contact persons

KNVI Customer master tax indicator

3.3 Vendor

LFA1 Vendor master

LFB1 Vendor per company code

LFB5 Vendor dunning data

LFM1 Purchasing organization data

LFM2 Purchasing data

LFBK Bank details

3.4 Customer – material info record

KNMT Customer material info record

3.5 Bank data

BNKA Master bank data

4 Characteristics:

4.1 Characteristics:

CABN Characteristics ( o.a. batch/vendor)

CABNT Characteristics description

CAWN Characteristics ( o.a. material)

CAWNT Characteristics description

AUSP Characteristic Values

4.2 Class types and objects :

TCLAO Several class types for object

TCLA Class types ( vb. lfa1 => v10 en 010)

TCLAT Class type text

TCLT Classifiable objects

TCLC Classification status

4.3 Links:

INOB Link between Internal Number and Object

KLAH Class header data

KSSK Allocation Table: Object (vb.matnr) to Class

KSML Characteristics for a class (internal number)

5 FI/CO :

5.1 FI :

5.1.1 Master data

SKA1 Accounts

BNKA Bank master record

5.1.2 Accounting documents // indices

BKPF Accounting documents

BSEG item level

BSID Accounting: Secondary index for customers

BSIK Accounting: Secondary index for vendors

BSIM Secondary Index, Documents for Material

BSIP Index for vendor validation of double documents

BSIS Accounting: Secondary index for G/L accounts

BSAD Accounting: Index for customers (cleared items)

BSAK Accounting: Index for vendors (cleared items)

BSAS Accounting: Index for G/L accounts (cleared items)

5.1.3 Payment run

REGUH Settlement data from payment program

REGUP Processed items from payment program

5.2 CO :

TKA01 Controlling areas

TKA02 Controlling area assignment

KEKO Product-costing header

KEPH Cost components for cost of goods manuf.

KALO Costing objects

KANZ Sales order items - costing objects

5.2.1 Cost center master data

CSKS Cost Center Master Data

CSKT Cost center texts

CRCO Assignment of Work Center to Cost Center

5.2.2 Cost center accounting

COSP CO Object: Cost Totals for External Postings

COEP CO Object: Line Items (by Period)

. COBK CO Object: Document header

COST CO Object: Price Totals

6 Sales and Distribution (SD) :

VBFA Document flow (alg.)

VTFA Flow shipping documents

6.1 Sales order:

VBAK Header data

VBAP Item data

VBPA Partners in sales order

VBKD Sales district data

VBEP Data related to line items, delivery lines

6.2 Billing document:

VBRK header data

VBRP Item data

6.3 Shipping:

VTTK Shipment header

VTTP Shipment item

VTTS Stage in transport

VTSP Stage in transport per shipment item

VTPA Shipment partners

VEKP Handling Unit - Header Table

VEPO Packing: Handling Unit Item (Contents)

6.4 Delivery:

LIKP Delivery header

LIPS Delivery item

6.5 Pricing:

KONH Conditions header

KONP Conditions items

KONV Procedure ( billing doc or sales order)

KOND

6.6 contracts:

VEDA Contract data

7 Material Management (MM) :

7.1 Material document

MKPF material document

MSEG material document (item level)

7.2 Purchasing

EKKO Purchase document

EKPO Purchase document (item level)

EKPV Shipping-Specific Data on Stock Tfr. for Purch. Doc. Item

EKET Delivery schedule

VETVG Delivery Due Index for Stock Transfer

EKES Order Acceptance/Fulfillment Confirmations

EKKN Account assignment in purchasing

EKAN Vendor address purchasing

EKPA Partner functions

EIPO Item export / import data

EINA Purchase info record (main data)

EINE Purchase info record (organisational data)

EORD Source list

EBAN Purchase requisition

EBKN Purchase Requisition Account Assignment

8 Warehouse Management (WM) :

8.1 Transfer requirement

LTBK Transfer requirement - header

LTBP Transfer requirement - item

8.2 Transfer order

LTAK Transfer order - header

LTAP Transfer order - item

8.3 Master data - stock positions

LQUA Quants

8.4 Inventory documents in WM

LINK Inventory document header

LINP Inventory document item

LINV Inventory data per quant

9 Quality Management (QM) :

9.1 Inspection lot / info record

QALS Inspection lot record

QAMB Link inspection lot - material document

QAVE Inspection usage decision

QDPS Inspection stages

QMAT Inspection type - material parameters

QINF Inspection info record (vendor - material)

QDQL Quality level

QDPS Inspection stages

9.2 Quality notification

TQ80 Notification types

QMEL Quality notification

QMFE Quality notification – items

QMUR Quality notification – causes

QMSM Quality notification – tasks

QMMA Quality notification – activities

QMIH Quality message - maintenance data excerpt

9.3 Certificate profile

QCVMT Certificate profile characteristic level: texts

QCVM Certificate profile characteristic level

QCVK Certificate profile header

10 Production Planning (PP)

10.1 Work center

CRHH Work center hierarchy

CRHS Hierarchy structure

CRHD Work center header

CRTX Text for the Work Center or Production Resource/Tool

CRCO Assignment of Work Center to Cost Center

KAKO Capacity Header Segment

CRCA Work Center Capacity Allocation

TC24 Person responsible for the workcenter

10.2 Routings/operations

MAPL Allocation of task lists to materials

PLAS Task list - selection of operations/activities

PLFH Task list - production resources/tools

PLFL Task list - sequences

PLKO Task list - header

PLKZ Task list: main header

PLPH Phases / suboperations

PLPO Task list operation / activity

PLPR Log collector for tasklists

PLMZ Allocation of BOM - items to operations

10.3 Bill of material

STKO BOM - header

STPO BOM - item

STAS BOMs - Item Selection

STPN BOMs - follow-up control

STPU BOM - sub-item

STZU Permanent BOM data

PLMZ Allocation of BOM - items to operations

MAST Material to BOM link

KDST Sales order to BOM link

10.4 Production orders

AUFK Production order headers

AFIH Maintenance order header

AUFM Goods movement for prod. order

AFKO Order header data PP orders

AFPO Order item

RESB Order componenten

AFVC Order operations

AFVV Quantities/dates/values in the operation

AFVU User fields of the operation

AFFL Work order sequence

AFFH PRT assignment data for the work order(routing)

JSTO Status profile

JEST Object status

AFRU Order completion confirmations

PRT’s voor production orders

AFFH PRT assignment data for the work order

CRVD_A Link of PRT to Document

DRAW Document Info Record

TDWA Document Types

TDWD Data Carrier/Network Nodes

TDWE Data Carrier Type

10.5 Planned orders

PLAF Planned orders

10.6 KANBAN

PKPS Kanban identification, control cycle

PKHD Kanban control cycle (header data)

PKER Error log for Kanban containers

10.7 Reservations

RESB Material reservations

RKPF header

10.8 Capacity planning

KBKO Header record for capacity requirements

KBED Capacity requirements records

KBEZ Add. data for table KBED (for indiv. capacities/splits)

10.9 Planned independent requirements

PBIM Independent requirements for material

PBED Independent requirement data

PBHI Independent requirement history

PBIV Independent requirement index

PBIC Independent requirement index for customer req.

11 Project system (PS)

11.1 Basic data

PRHI Work Breakdown Structure, Edges (Hierarchy Pointer)

PROJ Project definition

PRPS WBS (Work Breakdown Structure) Element Master Data

RPSCO Project info database: Costs, revenues, finances

MSPR Project stock

11.2 Equipment

EQUI Equipment master data

EQKT Equipment short text

EQUZ Equipment time segment

12 Plant maintenance (PM)

IHPA Plant Maintenance: Partners

OBJK Plant Maintenance Object List

ILOA PM Object Location and Account Assignment

AFIH Maintenance order header

12.1 Human resources

12.2 Settings

T582A Infotypes: Customer-Specific Settings

12.3 Master data

T527X Organizational Units

T528T Position Texts

T554T Attendance and Absence Texts

T501 Employee group

T503 Employee group, subgroup

T503K Employee subgroup

T510N Pay Scales for Annual Salaries (NA)

T549A Payroll Accounting Areas

T750X Vacancy

12.4 Infotypes

PA0001 Org. Assignment

PA0002 Personal Data

PA0006 Addresses

PA0007 Planned Working Time

PA0016 Contract elements

PA0008 Basic pay

PA0105 Communications

PA1007 Vacancies

PA1035 Training

PA2001 Absences

Other important table

JEST System Status with object number

TJ02 System status description.

MRP Related

MDKP Header Data for MRP Document

MDTB MRP Table

MDVL Planning file entry for long term planning

MDVM Enry in MRP file

PBVPV Material Index for consumption of planning

REUL Material stock transfer reservation index

SAFK Run schedule master data

SQ01 Abap query

EDMSG ALE message type table

1 Customising

1.1 General settings

1.1.1 Countries

T005 Countries

1.1.2 Currency

TCURC Currency codes

TCURR Wisselkoersen

TCURT Currency name

TCURX Decimal places for currencies.

1.1.3 Unit of measure

T006 Units of measure

1.1.4 Calendar functions

T247 Month names

TFACD Factory calendar definition

T015M Month names

TTZZ Time zones

TTZD Summer time rules

TTZDF Summer time rules (fixed annual dates)

TTZDV Summer time rules (variable dates)

TTZDT Summer time rules texts

TTZ5 Assign Time Tones to Countries

TTZ5S Assign time zones to regions

1.2 Enterprise structure

1.2.1 Definition

FI T880 Company

T001 Company code

CO TKA01 Controlling area

LO T001W Plant / sales organisation

T499S Locations

TSPA Division

SD TVKO Sales organisation / company code

TVTW Distribution channel

TVBUR Sales office

TVKBT Sales office text

TVKGR Sales group

TVGRT Sales group text

T171T Sales district text

MM T001L Storage locations

T024E Purchasing organization

T3001 Warehouse number

TVST Shipping point

TVLA Loading point

TTDS Transportation

1.2.2 Assignment

CO TKA02 Assign company code to controlling area

LO T001K Assign plant (valuation area) to company code

SD TVKO Sales organisation / company code

TVKOV Distribution channel / sales organisation

TVKOS Division to sales organization

TVTA Sales aria

TVKBZ Sales office to sales area

TVBVK Sales group to sales office

TVKWZ Plants to sales organization

MM T024E Purchasing organization / company code

T024W Plant to Purchase organization

T001K Link plant ( = valuation area) / company code

TVSWZ Shipping point to plant

T320 Assignment MM Storage Location to WM Warehouse

1.3 Financial accounting

1.3.1 Company code

T004 Chart of accounts

T077S Account group (g/l accounts)

T009 Fiscal year variants

T880 Global company data

T014 Credit control area

1.3.2 Fi document

T010O Posting period variant

T010P Posting Period Variant Names

T001B Permitted Posting Periods

T003 Document types

T012 House banks

1.4 Not categorized

T007a Tax keys

T134 Material types

T179 Materials: Product Hierarchies

T179T Materials: Product hierarchies: Texts

TJ02T Status text

TINC Customer incoterms

TVFK Billing doc types

T390 PM: Shop papers for print control

2 Basic data / administration

2.1 Workbench related tables

2.1.1 Data dictionary tables

DD02L Tables in SAP

DD02T Tables description

DD03L Field names in SAP

DD03T Field description in SAP

2.1.2 Workbench

TADIR Directory of R/3 Repository Objects

TRDIR System table TRDIR

TFDIR Function Module

TLIBG Person responsible for function class

TLIBT Function Group Short Texts

TFTIT Function Module Short Text

TSTC Transaction codes in SAP

TSTCT Transaction codes texts

T100 Message text (vb e000)

VARID Variant data

D020T Screen texts

TDEVC Development class

TDEVCT Texts for development classes

2.2 Administration

2.2.1 User administration

USR01 User master

USR02 Logon data

USR03 User address data

USR04 User master authorizations

USR11 User Master Texts for Profiles (USR10)

UST12 User master: Authorizations

USR12 User master authorization values

USR13 Short Texts for Authorizations

USR40 Prohibited passwords

TOBJ Objects

TOBC Authorization Object Classes

TPRPROF Profile Name for Activity Group

DEVACCESS Table for development user

2.2.2 Batch input queue

APQD DATA DEFINITION Queue

APQI Queue info definition

2.2.3 Job processing

TBTCO Job status overview table

TBTCP Batch job step overview

2.2.4 Spool

TSP02 Spool: Print requests

2.2.5 Runtime errors

SNAP Runtime errors

2.2.6 Message control

TNAPR Processing programs for output

NAST Message status

NACH Printer determination

2.2.7 EDI

EDIDC Control record

EDIDD Data record

EDID2 Data record 3.0 Version

EDIDS EDI status record

EDPAR Convert External < > Internal Partner Number

EDPVW EDI partner types

EDPI1 EDI partner profile inbound

EDPO1/2/3 EDI partner profile outbound

2.2.8 Change documents

CDHDR Change document header

CDPOS Change document positioned

JCDS Change Documents for System/User Statuses (Table JEST)

2.2.9 Reporting tree table

SERPTREE Reporting: tree structure

2.2.10 LIS structure/control tables

TMC4 Global Control Elements: LIS Info Structure

3 MASTER DATA:

3.1 Material master:

MARA Material master

MAKT Material text

MARC Material per plant / stock

MVKE Material master, sales data

MARD Storage location / stock

MSKA Sales order stock

MSPR Project stock

MARM Units of measure

MEAN International article number

PGMI Planning material

PROP Forecast parameters

MAPR Link MARC <=> PROP

MBEW Material valuation

MVER Material consumption

MLGN Material / Warehouse number

MLGT Material / Storage type

MPRP Forecast profiles

MDTB MRP table

MDKP Header data for MRP document

MLAN Tax data material master

MTQSS Material master view: QM

3.1.1 Basic data text (sap script)

STXB SAP script: Texts in non-SAP script format

STXH STXD SAP script text file header

STXL STXD SAP script text file lines

3.1.2 Batches

MCHA Batches

MCH1 Batches

MCHB Stock: batches

3.2 Customer master data

KNA1 Customer master

KNB1 Customer / company

KNVV Customer sales data

KNBK Bank details

KNVH Customer hierarchy

KNVP Customer partners

KNVS Shipment data for customer

KNVK Contact persons

KNVI Customer master tax indicator

3.3 Vendor

LFA1 Vendor master

LFB1 Vendor per company code

LFB5 Vendor dunning data

LFM1 Purchasing organization data

LFM2 Purchasing data

LFBK Bank details

3.4 Customer – material info record

KNMT Customer material info record

3.5 Bank data

BNKA Master bank data

4 Characteristics:

4.1 Characteristics:

CABN Characteristics ( o.a. batch/vendor)

CABNT Characteristics description

CAWN Characteristics ( o.a. material)

CAWNT Characteristics description

AUSP Characteristic Values

4.2 Class types and objects :

TCLAO Several class types for object

TCLA Class types ( vb. lfa1 => v10 en 010)

TCLAT Class type text

TCLT Classifiable objects

TCLC Classification status

4.3 Links:

INOB Link between Internal Number and Object

KLAH Class header data

KSSK Allocation Table: Object (vb.matnr) to Class

KSML Characteristics for a class (internal number)

5 FI/CO :

5.1 FI :

5.1.1 Master data

SKA1 Accounts

BNKA Bank master record

5.1.2 Accounting documents // indices

BKPF Accounting documents

BSEG item level

BSID Accounting: Secondary index for customers

BSIK Accounting: Secondary index for vendors

BSIM Secondary Index, Documents for Material

BSIP Index for vendor validation of double documents

BSIS Accounting: Secondary index for G/L accounts

BSAD Accounting: Index for customers (cleared items)

BSAK Accounting: Index for vendors (cleared items)

BSAS Accounting: Index for G/L accounts (cleared items)

5.1.3 Payment run

REGUH Settlement data from payment program

REGUP Processed items from payment program

5.2 CO :

TKA01 Controlling areas

TKA02 Controlling area assignment

KEKO Product-costing header

KEPH Cost components for cost of goods manuf.

KALO Costing objects

KANZ Sales order items - costing objects

5.2.1 Cost center master data

CSKS Cost Center Master Data

CSKT Cost center texts

CRCO Assignment of Work Center to Cost Center

5.2.2 Cost center accounting

COSP CO Object: Cost Totals for External Postings

COEP CO Object: Line Items (by Period)

. COBK CO Object: Document header

COST CO Object: Price Totals

6 Sales and Distribution (SD) :

VBFA Document flow (alg.)

VTFA Flow shipping documents

6.1 Sales order:

VBAK Header data

VBAP Item data

VBPA Partners in sales order

VBKD Sales district data

VBEP Data related to line items, delivery lines

6.2 Billing document:

VBRK header data

VBRP Item data

6.3 Shipping:

VTTK Shipment header

VTTP Shipment item

VTTS Stage in transport

VTSP Stage in transport per shipment item

VTPA Shipment partners

VEKP Handling Unit - Header Table

VEPO Packing: Handling Unit Item (Contents)

6.4 Delivery:

LIKP Delivery header

LIPS Delivery item

6.5 Pricing:

KONH Conditions header

KONP Conditions items

KONV Procedure ( billing doc or sales order)

KOND

6.6 contracts:

VEDA Contract data

7 Material Management (MM) :

7.1 Material document

MKPF material document

MSEG material document (item level)

7.2 Purchasing

EKKO Purchase document

EKPO Purchase document (item level)

EKPV Shipping-Specific Data on Stock Tfr. for Purch. Doc. Item

EKET Delivery schedule

VETVG Delivery Due Index for Stock Transfer

EKES Order Acceptance/Fulfillment Confirmations

EKKN Account assignment in purchasing

EKAN Vendor address purchasing

EKPA Partner functions

EIPO Item export / import data

EINA Purchase info record (main data)

EINE Purchase info record (organisational data)

EORD Source list

EBAN Purchase requisition

EBKN Purchase Requisition Account Assignment

8 Warehouse Management (WM) :

8.1 Transfer requirement

LTBK Transfer requirement - header

LTBP Transfer requirement - item

8.2 Transfer order

LTAK Transfer order - header

LTAP Transfer order - item

8.3 Master data - stock positions

LQUA Quants

8.4 Inventory documents in WM

LINK Inventory document header

LINP Inventory document item

LINV Inventory data per quant

9 Quality Management (QM) :

9.1 Inspection lot / info record

QALS Inspection lot record

QAMB Link inspection lot - material document

QAVE Inspection usage decision

QDPS Inspection stages

QMAT Inspection type - material parameters

QINF Inspection info record (vendor - material)

QDQL Quality level

QDPS Inspection stages

9.2 Quality notification

TQ80 Notification types

QMEL Quality notification

QMFE Quality notification – items

QMUR Quality notification – causes

QMSM Quality notification – tasks

QMMA Quality notification – activities

QMIH Quality message - maintenance data excerpt

9.3 Certificate profile

QCVMT Certificate profile characteristic level: texts

QCVM Certificate profile characteristic level

QCVK Certificate profile header

10 Production Planning (PP)

10.1 Work center

CRHH Work center hierarchy

CRHS Hierarchy structure

CRHD Work center header

CRTX Text for the Work Center or Production Resource/Tool

CRCO Assignment of Work Center to Cost Center

KAKO Capacity Header Segment

CRCA Work Center Capacity Allocation

TC24 Person responsible for the workcenter

10.2 Routings/operations

MAPL Allocation of task lists to materials

PLAS Task list - selection of operations/activities

PLFH Task list - production resources/tools

PLFL Task list - sequences

PLKO Task list - header

PLKZ Task list: main header

PLPH Phases / suboperations

PLPO Task list operation / activity

PLPR Log collector for tasklists

PLMZ Allocation of BOM - items to operations

10.3 Bill of material

STKO BOM - header

STPO BOM - item

STAS BOMs - Item Selection

STPN BOMs - follow-up control

STPU BOM - sub-item

STZU Permanent BOM data

PLMZ Allocation of BOM - items to operations

MAST Material to BOM link

KDST Sales order to BOM link

10.4 Production orders

AUFK Production order headers

AFIH Maintenance order header

AUFM Goods movement for prod. order

AFKO Order header data PP orders

AFPO Order item

RESB Order componenten

AFVC Order operations

AFVV Quantities/dates/values in the operation

AFVU User fields of the operation

AFFL Work order sequence

AFFH PRT assignment data for the work order(routing)

JSTO Status profile

JEST Object status

AFRU Order completion confirmations

PRT’s voor production orders

AFFH PRT assignment data for the work order

CRVD_A Link of PRT to Document

DRAW Document Info Record

TDWA Document Types

TDWD Data Carrier/Network Nodes

TDWE Data Carrier Type

10.5 Planned orders

PLAF Planned orders

10.6 KANBAN

PKPS Kanban identification, control cycle

PKHD Kanban control cycle (header data)

PKER Error log for Kanban containers

10.7 Reservations

RESB Material reservations

RKPF header

10.8 Capacity planning

KBKO Header record for capacity requirements

KBED Capacity requirements records

KBEZ Add. data for table KBED (for indiv. capacities/splits)

10.9 Planned independent requirements

PBIM Independent requirements for material

PBED Independent requirement data

PBHI Independent requirement history

PBIV Independent requirement index

PBIC Independent requirement index for customer req.

11 Project system (PS)

11.1 Basic data

PRHI Work Breakdown Structure, Edges (Hierarchy Pointer)

PROJ Project definition

PRPS WBS (Work Breakdown Structure) Element Master Data

RPSCO Project info database: Costs, revenues, finances

MSPR Project stock

11.2 Equipment

EQUI Equipment master data

EQKT Equipment short text

EQUZ Equipment time segment

12 Plant maintenance (PM)

IHPA Plant Maintenance: Partners

OBJK Plant Maintenance Object List

ILOA PM Object Location and Account Assignment

AFIH Maintenance order header

12.1 Human resources

12.2 Settings

T582A Infotypes: Customer-Specific Settings

12.3 Master data

T527X Organizational Units

T528T Position Texts

T554T Attendance and Absence Texts

T501 Employee group

T503 Employee group, subgroup

T503K Employee subgroup

T510N Pay Scales for Annual Salaries (NA)

T549A Payroll Accounting Areas

T750X Vacancy

12.4 Infotypes

PA0001 Org. Assignment

PA0002 Personal Data

PA0006 Addresses

PA0007 Planned Working Time

PA0016 Contract elements

PA0008 Basic pay

PA0105 Communications

PA1007 Vacancies

PA1035 Training

PA2001 Absences

Other important table

JEST System Status with object number

TJ02 System status description.

MRP Related

MDKP Header Data for MRP Document

MDTB MRP Table

MDVL Planning file entry for long term planning

MDVM Enry in MRP file

PBVPV Material Index for consumption of planning

REUL Material stock transfer reservation index

SAFK Run schedule master data

SQ01 Abap query

EDMSG ALE message type table

General Settings for data extraction

General Settings for data extraction:

In General Settings (SBIW) we make general settings for the data extraction from a source system into BW.

It includes 3 functions.

1. Maintain control parameters for data transfer

2. Limit Authorization for extraction

3. Check Delta Queue

1. Maintain Control Parameters for Data Transfer (SBIW)

We have 6 parameters which controls the data from SAP R/3 TO SAP BW.

2. Maximum Size of the Datapacket (KB)

3. Maximum lines/records in the Datapacket.

4. Frequency of IDOC.

5. Maximum number of parallel process

6. Target system for batch job.

Source System:

Enter the logical system of your source client and assign the control parameters you selected to it.

We can find the source client in the source system by choosing path.

Tools....> Administration.......>Client Maintenance or T-Code SCC4.

Display the list of clients:

Basically there are 2 types of clients:

1. Administrative Clients: Eg: 000,066

2. Active/Working clients: 800,812.....

Maximum size of the Data packet:

When you transfer data into BW, the individual data records are set in packets of variable size. We can use this parameter to control how large a typical datapacket like this is. The default size of datapacket is 10000 Kbytes. The memory requirement not only depends on settings of the datapacket but also on the size of the transfer structure and the memory requirement of the relevant extractor.

Frequency of IDoc:

The specified frequency determines the number of IDoc’s than an info IDoc is to be sent, or how many data IDoc an Info IDoc describes.

Frequency 1 is set by default. This means that an Info IDoc follows for every data IDoc, you should select a frequency between 5 and 10 but not higher than 20. The bigger the data IDoc packet. The lower the frequency setting should be the help of every information IDoc you can check the BW Monitor to see if there are any errors in the loading process. If no errors then the traffic

The Info IDoc contains information such as whether the respective data IDoc were uploaded correctly.

The T-Codes related to IDoc’s are, IDOC, WE02, WE05, WE18, WE19, WE20, BD87, SALE.

Maximum Number of parallel process for the Delta transfer:

Enter a number larger than 0. The maximum number of parallel process is set by default at the ideal parameter selection depends on the configuration of the application server which you use for transferring the data.

Maximum lines/records in the data packet:

Indicates maximum number of records maintained data packet/data package. This parameter is settings are proportnate of request.

Target system for Batch Job:

Enter the name of the application server on which the extraction job is to be processed. To determine the name of the application server then choose the path.

Tools.....>Path.....> Administration......>Monitor.....>System Monitoring......>Server

How to maintain different data packet sizes for individual data sources:

Enter the size of the packet in setting for sending data in the scheduler screen in the BW System.

Navigation:

At the time of creating info package.....>scheduler.....>scheduler menu.....>datasource default data transfer

2. Limit Authorizations for Extractions:

With this step we can exclude datasource from the extraction data that is stored in the extract structure of this datasource for single BI systems from extraction. If you want to exclude datasource for all connected BI systems from the extraction, then select edit datasource.

It includes 3 parameters:

1. Datasource: The name of the datasource to be excluded.

2. BW System: The name of the BW System to which the datasource.

3. Excluded Extract structure: The name of the extract structure to be excluded from the data extraction.

3. Check Delta Queue:

The delta queue is a datastore in the source system, in which data records are either written automatically using an update process or by extraction using a function module, following a data request from BI.

1. Status of the update

2. Name of the datasource

3. Name of the BI system to which datasource provides data

4. Total delta records for the latest update

Overall status

The update mode includes 1. Delta update (D1)

2, Delta Repitition (Repita Delta (RD1)

It is possible to delete the data records for datasource by setting datasource and selecting delete data and metadata in a queue.

In General Settings (SBIW) we make general settings for the data extraction from a source system into BW.

It includes 3 functions.

1. Maintain control parameters for data transfer

2. Limit Authorization for extraction

3. Check Delta Queue

1. Maintain Control Parameters for Data Transfer (SBIW)

We have 6 parameters which controls the data from SAP R/3 TO SAP BW.

.

Source System

2. Maximum Size of the Datapacket (KB)

3. Maximum lines/records in the Datapacket.

4. Frequency of IDOC.

5. Maximum number of parallel process

6. Target system for batch job.

Source System:

Enter the logical system of your source client and assign the control parameters you selected to it.

We can find the source client in the source system by choosing path.

Tools....> Administration.......>Client Maintenance or T-Code SCC4.

Display the list of clients:

Basically there are 2 types of clients:

1. Administrative Clients: Eg: 000,066

2. Active/Working clients: 800,812.....

Maximum size of the Data packet:

When you transfer data into BW, the individual data records are set in packets of variable size. We can use this parameter to control how large a typical datapacket like this is. The default size of datapacket is 10000 Kbytes. The memory requirement not only depends on settings of the datapacket but also on the size of the transfer structure and the memory requirement of the relevant extractor.

Frequency of IDoc:

The specified frequency determines the number of IDoc’s than an info IDoc is to be sent, or how many data IDoc an Info IDoc describes.

Frequency 1 is set by default. This means that an Info IDoc follows for every data IDoc, you should select a frequency between 5 and 10 but not higher than 20. The bigger the data IDoc packet. The lower the frequency setting should be the help of every information IDoc you can check the BW Monitor to see if there are any errors in the loading process. If no errors then the traffic

The Info IDoc contains information such as whether the respective data IDoc were uploaded correctly.

The T-Codes related to IDoc’s are, IDOC, WE02, WE05, WE18, WE19, WE20, BD87, SALE.

Maximum Number of parallel process for the Delta transfer:

Enter a number larger than 0. The maximum number of parallel process is set by default at the ideal parameter selection depends on the configuration of the application server which you use for transferring the data.

Maximum lines/records in the data packet:

Indicates maximum number of records maintained data packet/data package. This parameter is settings are proportnate of request.

Target system for Batch Job:

Enter the name of the application server on which the extraction job is to be processed. To determine the name of the application server then choose the path.

Tools.....>Path.....> Administration......>Monitor.....>System Monitoring......>Server

How to maintain different data packet sizes for individual data sources:

Enter the size of the packet in setting for sending data in the scheduler screen in the BW System.

Navigation:

At the time of creating info package.....>scheduler.....>scheduler menu.....>datasource default data transfer

2. Limit Authorizations for Extractions:

With this step we can exclude datasource from the extraction data that is stored in the extract structure of this datasource for single BI systems from extraction. If you want to exclude datasource for all connected BI systems from the extraction, then select edit datasource.

Subsequent processing and delete datasource

It includes 3 parameters:

1. Datasource: The name of the datasource to be excluded.

2. BW System: The name of the BW System to which the datasource.

3. Excluded Extract structure: The name of the extract structure to be excluded from the data extraction.

3. Check Delta Queue:

The delta queue is a datastore in the source system, in which data records are either written automatically using an update process or by extraction using a function module, following a data request from BI.

The data records are transferred from BI Scheduler into BI when a delta request takes place. The data is compressed in delta queue. It can be request by more than one BI system. The delta queue can also be repeated meaning that data from recent extraction process is stored in the delta queue. The repeat mode of delta queue is target system specific. It includes the following parameters.

1. Status of the update

2. Name of the datasource

3. Name of the BI system to which datasource provides data

4. Total delta records for the latest update

Overall status

The update mode includes 1. Delta update (D1)

2, Delta Repitition (Repita Delta (RD1)

It is possible to delete the data records for datasource by setting datasource and selecting delete data and metadata in a queue.

Characteristic Value Authorization

Characteristic Value Authorization - BI 7.0

How to create Info Object level (Characteristic Value) Authorization for a Reporting User in BI 7.0

Scenario: There are 5 sales organizations and we are going to restrict a reporting user ( TEST ) to access only 2 sales organization data out of the 5. In this eg.1000 and 2000 are the sales organizations of the user TEST for which we are going to give access. So whenever the user TEST executes the report, he will only be able to see the Sales organizations 1000 and 2000 in the report.

Step - 1: Mark the InfoObject Authorization Relevant & Activate it.

Step - 2: Go to Tcode - RSECADMIN

Under Maintenance - Enter the name of the Authorization Object and click Create Authorization.

Insert Sales Organization Info object as shown below. Also included the other SAP recommended objects 1.0TCAACTVT, 2.0TCAIPROV and 3.0TCAVALID.

Maintain the Values for these Objects. Select 0Salesorg and click Details.

Eg: Values 1000 and 2000 are maintained for Sales Organization.

Note: Also include all Authorization Relevant Objects which are used in that InfoProvider in addition to the above additional 3 objects otherwise you may get "No Authorization" error when you execute the query.

Step - 3: Tcode - RSU01 Assign User to Authorization Object

Enter the name of the user to be assigned with the authorization object and click the change button.

The select the relevant authorization object and save.

Note: 0BI_ALL is the authorization object to access all the info objects which are authorization relevant.

Step - 4: Create Authorization Variable in Query Designer

Create an Authorization Variable - Variable with Processing by Authorization in Query Designer as Below for Sales Organization.

Restrict the Sales Organization with the Authorization Variable and execute the query.

How to create Info Object level (Characteristic Value) Authorization for a Reporting User in BI 7.0

Scenario: There are 5 sales organizations and we are going to restrict a reporting user ( TEST ) to access only 2 sales organization data out of the 5. In this eg.1000 and 2000 are the sales organizations of the user TEST for which we are going to give access. So whenever the user TEST executes the report, he will only be able to see the Sales organizations 1000 and 2000 in the report.

Step - 1: Mark the InfoObject Authorization Relevant & Activate it.

Step - 2: Go to Tcode - RSECADMIN

Under Maintenance - Enter the name of the Authorization Object and click Create Authorization.

Insert Sales Organization Info object as shown below. Also included the other SAP recommended objects 1.0TCAACTVT, 2.0TCAIPROV and 3.0TCAVALID.

Maintain the Values for these Objects. Select 0Salesorg and click Details.

Eg: Values 1000 and 2000 are maintained for Sales Organization.

Note: Also include all Authorization Relevant Objects which are used in that InfoProvider in addition to the above additional 3 objects otherwise you may get "No Authorization" error when you execute the query.

Step - 3: Tcode - RSU01 Assign User to Authorization Object

Enter the name of the user to be assigned with the authorization object and click the change button.

The select the relevant authorization object and save.

Note: 0BI_ALL is the authorization object to access all the info objects which are authorization relevant.

Step - 4: Create Authorization Variable in Query Designer

Create an Authorization Variable - Variable with Processing by Authorization in Query Designer as Below for Sales Organization.

Restrict the Sales Organization with the Authorization Variable and execute the query.

Sunday, December 11, 2011

Saturday, December 10, 2011

Friday, December 9, 2011

Generic extraction

Generic extraction:

Once you have the requirement is clear then Logon to Ecc system,

If u r requirement is from single table then go by Table method, if more than one table then first create view in SE11 T-code ,then using the same view create DS .

RSO2-T-code to create generic data source

First go to se11 and write from which all the fields u want data and check for that field is there any standard info obj by description in BI system,if present check the properties are matching with field properties in ecc table from which u want to extract data.

1) Select the type of DS u want to create based on the table u take, give the tech name and click on create icon.

2) Then in the next screen give the applic.comp (SD, mm, hr) this will be decided based on the table, and it belongs to which application.

Then give the 3 descriptions, then give the table name and click on save.

Then u get below screen for selection, select from which fields u want to get data, hide remaining fields, if u don’t hide also nothing will happen.

Then click on save, u r ds is ready now.

then set the generic extraction by clicking on GENERIC DELTA icon, then a small popup window will appear, here set the update method u want to use to extract delta records, then set the field from which system will identify the delta records,

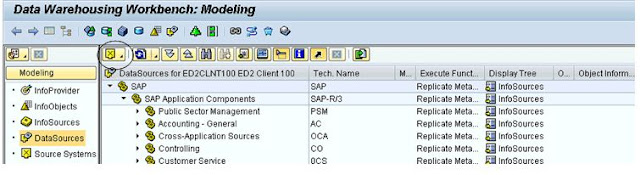

LOGON TO BI SYSTEM , RSA1DATA SOURCE TAB SELCT THE APPLICATION WHICH U GIVEN IN RSO2 SCREEN AND RIGHT CLICK AND SELECT REPLICATE META DATANOW U R DS WILL GET COPIED TO BI SIDESELECT DS AND CREATE INFO PACKAGE AND RUN THEN DATA WILL LOAD TO PSA.

Before replicating if you search the ds you will not find, to make available we do replicate, when we do replicate only structure copies no data will come.

1) Choose u r source system and select the application and do replicate

2) Create info package and run it to load data till psa.

3) next to create the target object(dso/cube)to store data, first we have to find the info objects for the fields you selected ,we can find out them by copying the description of the field in table and search in info objects tab in BI, if u find any info obj with same description first check the properties of the info obj with the field, if matches u can use it, if not create new info obj with same description and same propertied(data type, length).

4) After finding/creation of all info objects create the dso/cube and activate.

5) Then select the ds and right click and select create transformations and activate.

6) Then create DTP and run. And check the data.

Once you have the requirement is clear then Logon to Ecc system,

If u r requirement is from single table then go by Table method, if more than one table then first create view in SE11 T-code ,then using the same view create DS .

RSO2-T-code to create generic data source

First go to se11 and write from which all the fields u want data and check for that field is there any standard info obj by description in BI system,if present check the properties are matching with field properties in ecc table from which u want to extract data.

1) Select the type of DS u want to create based on the table u take, give the tech name and click on create icon.

2) Then in the next screen give the applic.comp (SD, mm, hr) this will be decided based on the table, and it belongs to which application.

Then give the 3 descriptions, then give the table name and click on save.

Then u get below screen for selection, select from which fields u want to get data, hide remaining fields, if u don’t hide also nothing will happen.

Then click on save, u r ds is ready now.

then set the generic extraction by clicking on GENERIC DELTA icon, then a small popup window will appear, here set the update method u want to use to extract delta records, then set the field from which system will identify the delta records,

BI SIDE STEPS TO DO

LOGON TO BI SYSTEM , RSA1DATA SOURCE TAB SELCT THE APPLICATION WHICH U GIVEN IN RSO2 SCREEN AND RIGHT CLICK AND SELECT REPLICATE META DATANOW U R DS WILL GET COPIED TO BI SIDESELECT DS AND CREATE INFO PACKAGE AND RUN THEN DATA WILL LOAD TO PSA.

Before replicating if you search the ds you will not find, to make available we do replicate, when we do replicate only structure copies no data will come.

1) Choose u r source system and select the application and do replicate

2) Create info package and run it to load data till psa.

3) next to create the target object(dso/cube)to store data, first we have to find the info objects for the fields you selected ,we can find out them by copying the description of the field in table and search in info objects tab in BI, if u find any info obj with same description first check the properties of the info obj with the field, if matches u can use it, if not create new info obj with same description and same propertied(data type, length).

4) After finding/creation of all info objects create the dso/cube and activate.

5) Then select the ds and right click and select create transformations and activate.

6) Then create DTP and run. And check the data.

InfoCube Compressing:

InfoCube – Compressing:

For theory go through the links below.

Go to RSA1

under Modeling --> Choose InfoProvider --> Info Area and then --> Select your InfoCube

under Modeling --> Choose InfoProvider --> Info Area and then --> Select your InfoCube

Right Click on your infocube --> from context menu --> choose Manage

Once you are in manage data Targets screen:

Find out the request numbers – decide till what request id you want to compress

Find out the request numbers – decide till what request id you want to compress

Go to Collapse tab – under compress --> choose request ID and click Release

The selected request ID and anything below will be compressed.

What is happening behind the scene is “After the compression, the F fact table contains no more data.

Instead, the compressed data now appear in the E fact table.”

Instead, the compressed data now appear in the E fact table.”

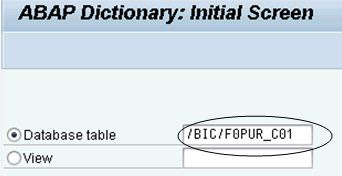

Before going to collapse tab check the numb of records in F table in SE11 T-code.

Give the table name as shown above and click on Display and check the records.

Similarly after doing compression do same steps and check data in E table.

Once compression is done your F-Table gets empty.

Below is the manage screen

If u want compression to happen automatically, add the process type (compression) in process chain after rollup process if any aggregates exist, else add after create index process.

After clicking on release then go to recq tab and see the compression status (green tick mark) which tells that compression is success. If u find clock symbol indicates still running.

Subscribe to:

Comments (Atom)